SW-1050B is our primarily new designed double side laminator for large width paper size in China, to solve the problem of two times lamination, making more profits for users

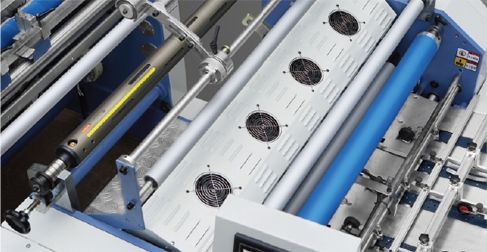

Instant Electromagnetic Heater

heat up time shorten to 90 seconds,

accurate temperature control:±1℃

Single and Double Sided Lamination

| Max Paper Size | 1050X820mm |

| Min Paper Size | 350x350 mm |

| Paper Thickness | 105-500 g/m2 |

| Laminating Speed | 0-65 m/min |

| Gross Power | 35kw |

| Weight | 4400 kg |

| Overall Dimensions | 6500x2200x1900 mm |

| Pre-stacker | 1850mm |

Dual electromagnetic heating system

1. Auto Feeder | 2. Electromagnetic Heater |

|  |

This machine is equipped with a paper pre-stacker, Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously fed into the machine | Equipped with advanced electromagnetic heater. Fast pre-heating. Energy saving. Environmental protection. |

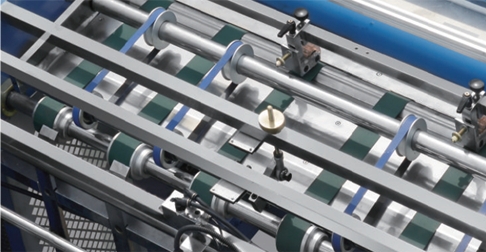

3. Human-computer interface | 4. Separation system |

|  |

A user-friendly interface system with a color touch screen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine speeds. | Pneumatic separation system to separate the paper stably and quickly. |

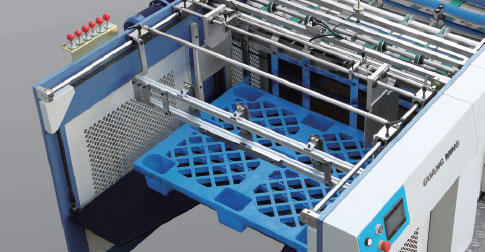

5. Corrugated Delivery | 6. Automatic Stacker |

|  |

A corrugated delivery system collects paper easily. | Automatic stacker receive the sheets quickly in order without stop the machine as well as counter the sheets |

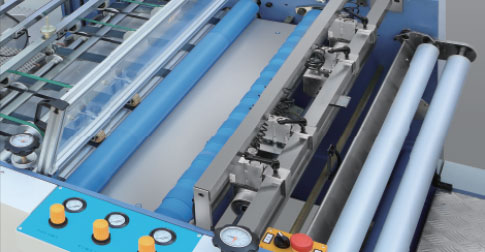

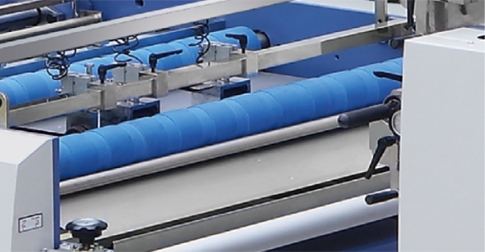

7. Film Loader | 8. Anti-curvature Device |

|  |

Operating the film loader is easy and efficient to use. | The machine is equipped with an anti-curl device, which ensures that paper remains flat and smooth during the lamination process. |

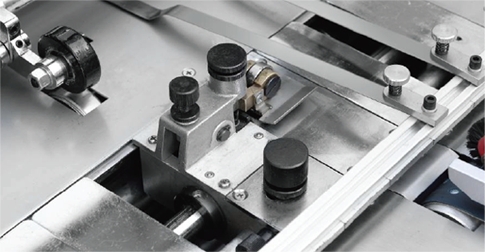

9. Side Lay Regulator | |

| |

The Servo controller and Side Lay Mechanism guarantees precise paper alignment at all times |