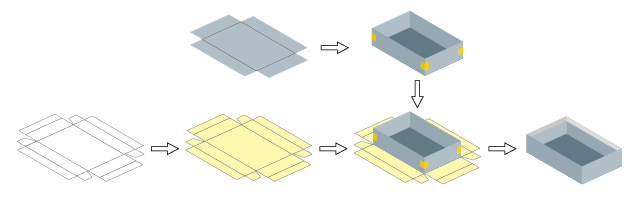

The cardboard box is pasted corners and formed, positioned onto the paper, pressed and wrapped. All processes are finished in one machine. It’s applicable to make high grade small rigid boxes, such as jewelry box, ring box etc.

| Model | RB240 |

| Size of paper | Min.305*450mm Max.45*110mm |

| Paper thickness | 80-160g/m^2 |

| Maximum size of the board | 230*380mm |

| Cardboard thickness | 0.5-3mm |

| Carton (finished product) dimensions | Min.35*45*10mm Max.160*240*80mm |

| Fold in paper edge size | Min.8mm Max.20mm |

| Speed up to | 32pcs/min |

| Machine dimension | L4500×W4000×H2600 |

| Machine weight | 3300kg |

Remark:

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

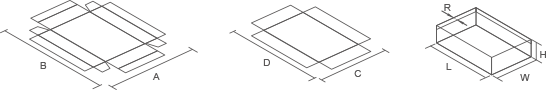

W+2H-4T≤C(Max)

L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max)

B(Min)≤L+2H+2T+2R≤B(Max)

|  |

| Digital adjustment of sizes: Adopt new design of servo and pneumatic control structure to wrap the box, fast digital adjustment of sizes | New servo controlled post-sucked type paper feeder: New designed servo controlled paper feeder adopts post-sucking pre-pushing type to convey paper which |

|  |

| Line-touch designed copper scraper: The copper scraper cooperates with the glue roller by line-touch design which makes the scraper more durable | Concentrated lubrication system: The concentrated oil system fully ensures each parts lubricating and the steady running of machine |

| |

| Glue viscosity meter: Auto glue viscosity meter efficiently adjusts the glue stickiness which ensures the quality of finished products |