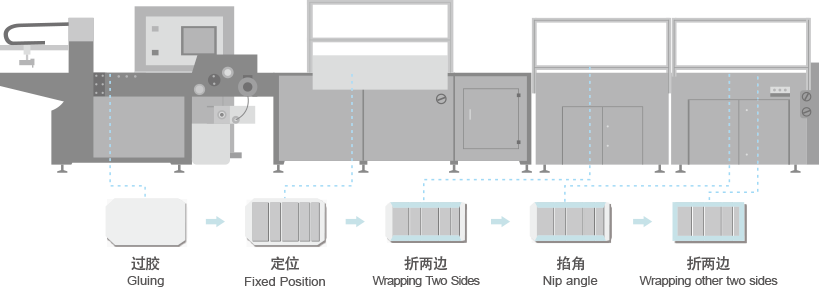

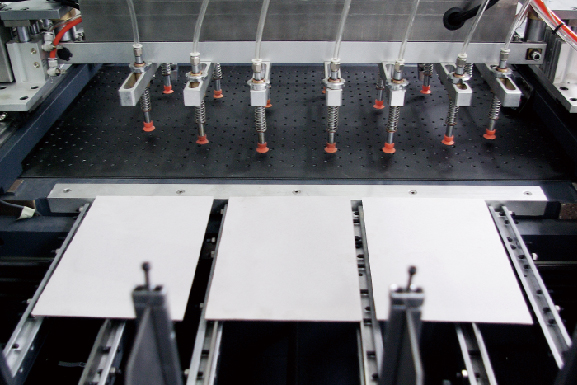

Keep improving to ensure stable and reliable paper transmission. Transmission of

facial tissue adopts automatic paper transmission feeder with mutually combined

with vacuum suction separated paper and computer controlled vacuum blower

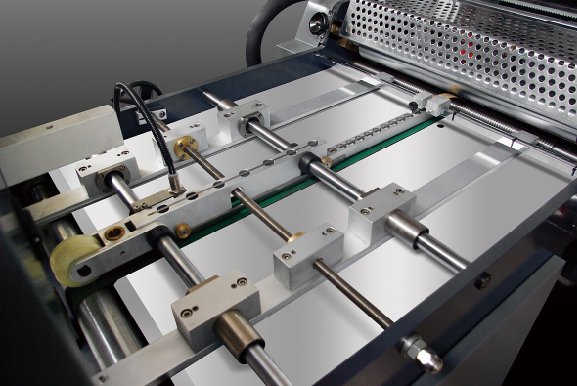

wheel paper delivery. Facial tissue enters band steel ball roller conveyer’s new

guiding rail for positioning, and then automatically coat glue for re-adoption of

optical fiber precise tracking error correction device. It adopts unique development

philosophy to solve problems including getting dirty and scratching. Through

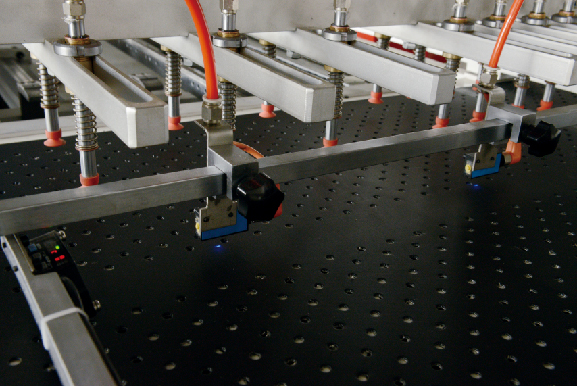

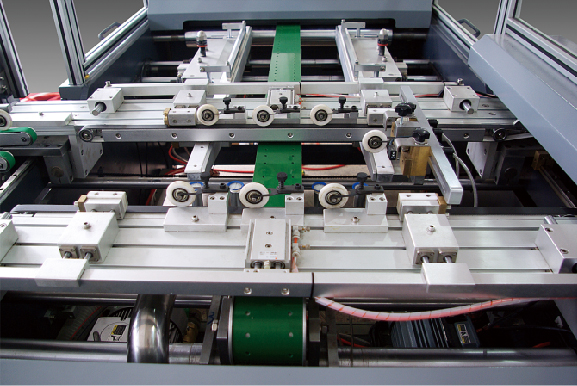

belt-oriented chaff transmission system developed by unique professional

technique, sucker manipulator transmits product onto vacuum air-transmission

conveyor belt for transmission which can avoid phenomenon including surface

occurring getting dirty and scratching to meet requirements for high-quality

products.

| Model | QFM460B | QFM600B |

| Length of paper | 210-830mm | 260-1030mm |

| Width of paper | 130-460mm | 130-600mm |

| Thickness of paper | 80-200g/m2 | 80-200g/m2 |

| Thickness of cardboard | 1-3mm | 1-3mm |

| Min width of spine | 8mm | 8mm |

| Speed | 0-30pcs/min | 0-30pcs/min |

| Power | 12kw | 13kw |

| Weight | 3000kg | 4000kg |

| Dimension | 7000*2100*1260mm | 8900*2250*1450mm |

|  |

Automatic error correction device for improvement of accuracy of cardboard positioning. | Optical fiber precise detection to improve accuracy of cardboard accuracy |

|  |

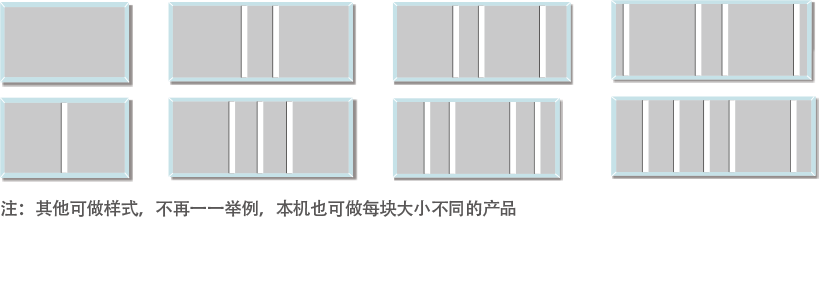

This technology has solved difficulties including its hemming and scratching for narrower cardboard. | It has improved efficiency for materials receiving and counting of finished products of chaff. |