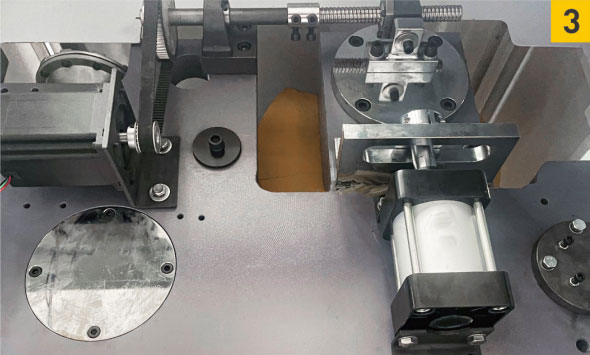

1.Upper knife roller has the British cutter method to effectively reduce the load and noise during paper

cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for

precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is

made of cast iron integrally formed and cast, and then precision processed, with good stability

2.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap,

and more. The touch screen controls work in conjunction with a Siemens PLC.

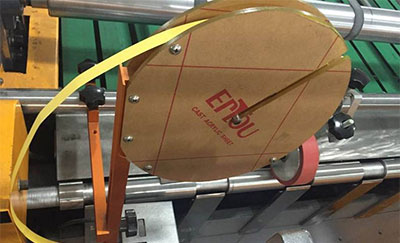

3.Three sets of slitting knife unit to have a high speed, smooth and powerless trimming and slitting,

with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

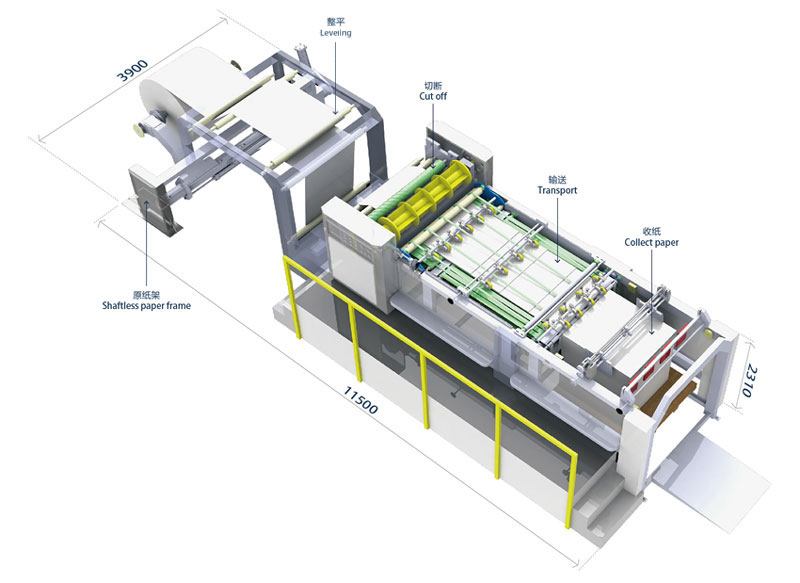

HSCJ-B series is an economical model released for customers with limited production space.

Driven by AC servo motor, controlled by UK motion, machine can cut paper stably in high speed.

Germany precise bearing and cutting knife assure the high cutting precision.

Touch interface controlis simple to operate.

Reasonable inflection device ensures smooth of paper.

The single-roll machine covers a less space, perform well in limited area and is economical.

|  |

MOTORIZED DOUBLE DECURLER This newly designed decurler can flatten the paper with a much better result than the conventional decurler system, which enable this machine practically to run thick board till 5oogsm | ELECTRIC CONTROL PART The man-machine interface and HZU processor, mainly used for the input of production data, monitoring of equipment operating status and system fault indication.The rotary horizontal cutter is driven by KymmeneTlSMGlk drive with fast operation and accurate positioning based on production, and actual speed from pulling roller feedback by encoder. |

|  |

AUTOMATICALLY ADJUST THE ANGLE (PAPER ALIGNING SYSTEM) The stepper motor precisely controls the precision screw and adjusts the inclination of the cutter group, so as to effectively ensure the right Angle of paper and reduce the error rate and loss caused by manual adjustment. | AUTOMATIC PILE ALLGNMENT DEVICE AT DELIVERY SECTION Lift automatically moves down when the pile is stacked to a consider- able height. The stacker table has fnishing function of three sides, one side is vibrated by motor, others by air, hand wheel to adjust the position of paper to improve the simplicity and safety of operation. |

| Upper knife roll has the British cutter method to reduce To steel welding gave precision machining, and dynamic balance adjustment, effectively reduce the vibration and noise of the high-speed operation. Rotary cutting knife is made of special alloy steel |

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm 2)Max Reel width: 1100mm/1400mm/1700mm/1900mm 3)Min Reel width: 300mm 4)Core size : 3"6"12" ( optional Mechanical chuck) 5)Hydraulic driving : 3.5kw 6)Clip arm move forward or back driven by hydraulic 7)Clip arm up or down driven by hydraulic 8)Pneumatic brake system 9)Roll with related bracket |  |

| Slitting knife Three sets of slitting knife unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting. |

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. (Chain type, automatic up and down, more stable operation and service life) Conveyor system with mult-stage: from high speed to low speed. First to separate the cut paper quickly, and then overlap the paper, collect and pile the paper. |  |

| Electronic control INOVANCE Servo, INOVANCE PLC, Schneider, Eaton. |

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, the side of the motor to drive the paper, the paper, on both sides by high-quality motor jogger to adjust the amplitude of the paper manually to improve the simplicity and safety of the operation. |  |

| Transport department The fast/slow speed belt is controlled by the stepless frequency converter, which automatically tracks the knife speed and adjusts the belt speed, so that the paper can be perfectly overlapped. |

Auto counting and Automatic marking Type: Insert after counting precisely Function: After inputting number of paper pieces in HMI, then it can work according to requirements. Auto-tension control Put the paper roll diameter and paper weight number into touching screen, the tension will be controlled by computer Automatically. |  |

| Model | HSCJ1100B/1400B/1700B/1900B |

Reference weight of cutting-paper | 30-550g |

Model of cutting paper | The upper knife cut reciprocally and the down knife is fixed |

Cutting accuracy | +/-0.3mm |

| Gross weight | 10.000kgs/13.000kgs |

Total power | 28kW |

Power consumption | AC380V/220vx50Hz |

Maximum cutting speed | 300cuts/min |

Maximum cutting meter speed | 300m/min |

Cutting length range | 400-1650mm |

Paper-piling height | 1400mm |

Max.roll diameter | 1800mm(71")Max |

Maximum paper-cutting width | 1100mm/1400mm/1700mm/1900mm |

The format of slitting | 2sheets |

| The request for air compressor | Max.5.5kg/cm2×5m3/min |

Blade tungsten steel

Cast iron main

Imports of electrical appliances

Pneumatic slitting knife

Dust removal

Color code tracking system

Motorized double decurler