1. Automatic Splicer

High performance automatic twin-head paper splicer with Taiwan control system, can splice paper automatically, perform out by high flexibility and long service life, suitable for base paper which grams of 80g/m²-400g/m².

2. Intelligent Pallet Placement

6 degrees of freedom industrial robot is an universal type easy to maintain. Equipped with an high-precision reducer on each joint, it can flexibly complete works like handling, stacking, assembly and injection molding.

3. Auto-Material Flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor, and uses the motor drive the material transport in ultra-low position straightly, which is a modular design and reach high degree of standardization. Hidden photoelectric switch can prevent photoelectric sensor or cardboard damage, servo motor built-in to save space, reversible operation, fexible adjustment, basically mainte-nance-free.

4. Non-Stop Paper Collection

Combined the international advanced concept, we designed non-stop paper collection system, is the latest product with independent intellectual property rights we won. lt is composed of short insert plate, long insert plate, friction belt and various auxiliary accessories. When the paper on the lifting platform reaches the rated amount, the short insert board lifts the end of the subsequent paper, and the long one hold the stack to act as collecting platform, so that workers or other automatic equipment can carry the stack. So as to achieve non-stop and continuous paper collecting, effectivelyimprove effciency and reduce costs.

5. Slitting & Trimming Knives Automatic Change System

APS-L series high-precision automatic positioning and slitting system matches high-precision sliting requirements. inteligently, accurately and rapidly, the sliting and trimming knives is auto-changing by manipulator,thus greatly improving the ability and effciency when product variety changing.According to different cutting requirements, it can work out diferent cutting solutions by coordinating with different knife, such as automatic type, manual type, connected type and pressure cutting type sliting knife, and electronic knife, etc.

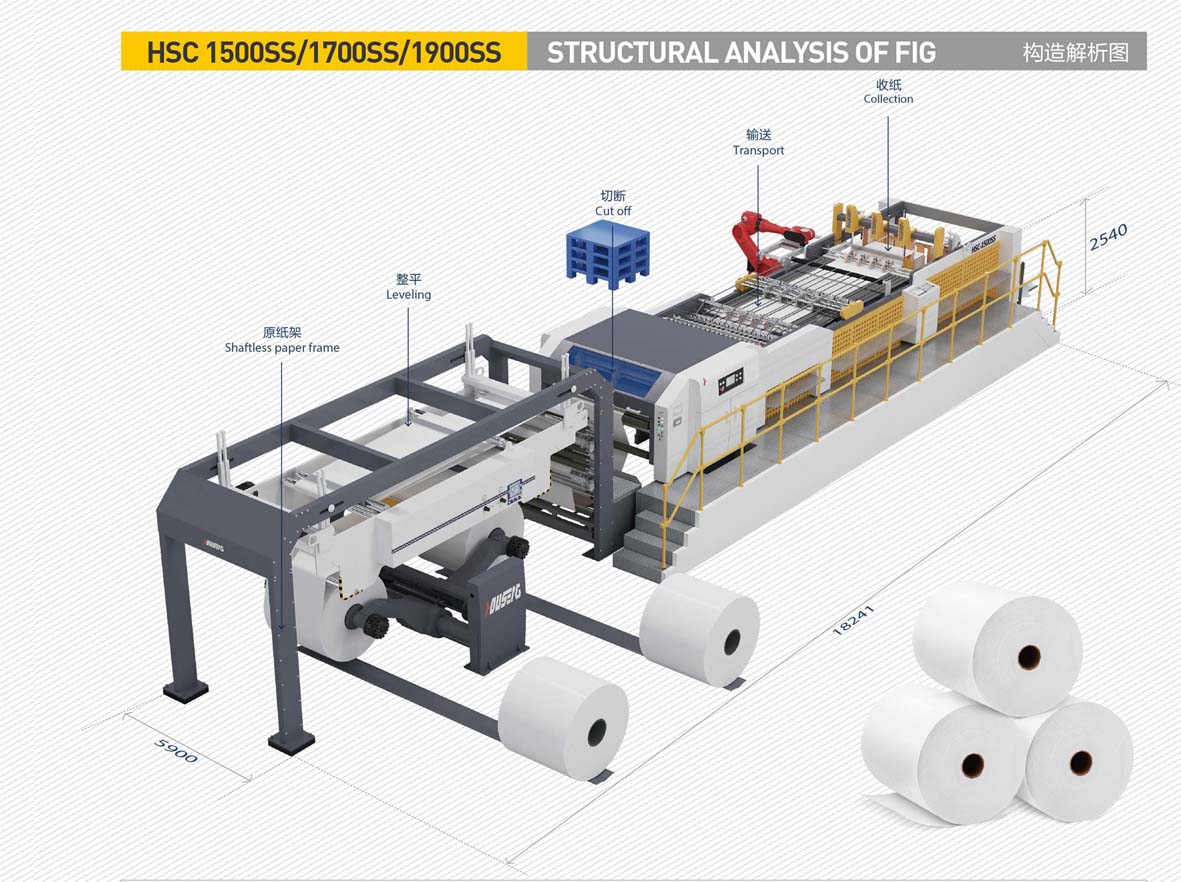

| ITEM | PARAMETERS | Cutting Length | Speed(m/min) | Speed (cuts/min) |

| Model | HSC 1500SS/1700SS/1900SS | 1600≤X | 210 | <131 |

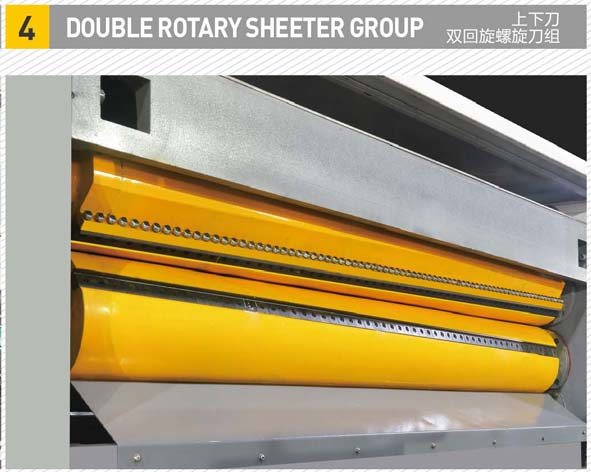

| Cutting Pattern | Double rotary sheeter | 1400≤X<1600 | 260 | ≥162<185 |

| Range ofGram Weight | 80-1000gsm | 1200≤X<1400 | 280 | ≥200<233 |

| Max.Roll Diameter | 1800mm(71”)Max | 1000≤X<1200 | 300 | ≥250<300 |

| Max.Paper Cutting Width | 1500mm/1700mm/1900mm | 800≤X<1000 | 300 | ≥300<375 |

| Total Power | 108kW | 700≤X<800 | 300 | ≥375<400 |

| Cutting Length | 400-1650mm | 650≤X<700 | 230 | ≥328<353 |

| Cutting Accuracy | +/-0.15mm | 600≤X<650 | 180 | ≥246<300 |

| Air Compressor Requirement | 0.8MPa | 550≤X<600 | 160 | ≥266<290 |

| Weight | 26000kgs/28000kgs | 500≤X<550 | 120 | ≥218<240 |

| Overall Dimension | L18241×W5900×H2533mm | 450≤X<500 | 90 | ≥180<200 |

| 400≤X<450 | 70 | ≥155<175 |

|  |  |

|  |  |

| Cutting Unit The double KNIFE cutting unit has a synchronic rotary cutting knife |

Double Arm Unwind stand with web tension controls and pneumatic brake units. |

|

| Three sets of MAXCESS pneumatic slitting knife ensure stable and clean |

Electric control partAdopt German imports of Siemens PLC and UK OF CT servo drive control system,make the operation more convenient, automation,cutting length, number and the total number of finished products, etc.,can be directly in touch screen input.High efficiency and energy saving of high power CT servo drive rotary knife shaft,and cooperate with the energy storage tank,effectively reduce electricity consumption,improve the efficiency, reduce the production cost. |  |

| Transportation partsPatent device-A precision structure can adjust the synchronous deceleration wheel,easy to operate, it is effective to protect surface of paper,so there will be no scratching on surface,and also will not have the facula whenever speed is high or low. |

Automatic splicer (optional)High performance automatic splicer is twin-head automatic paper machine.The control system is from Taiwan with the features of long service life,high flexibility, and automatic splicer as soon as theimperfect broken paper is sensed,easily for operation for 100 to 500 GSM papers. |

|

| Slitting & trimming knives automatic change (optional)The slitting & trimming knives are rapidly automatically changedby through a pair of smart and precision mechanical hands,which can greatly improve your production efficiencyand its production performance on the frequent size changes of paper.According to different cutting requirements,It can be coordinate with different knife type to form adifferent cutting solutions for different cutting requirementssuch as electronic knife, automatic type,manual type, Siamese type,press-cutting type, etc. |

Automatic logistics system:Tray chain conveyor mainly adopts five row straight plate chain transport,motor driven design, its function is to achieve linear material transport,ultra-low transport. A series of pallet chain conveyors combined in series witheach other have realized the long or short distance linear conveying ofmaterials according to the region and process design.Modular design, high degree of standardizationflexible process arrangement and adjustment,the equipment is basically maintenance-free. |

|

| Intelligent tray placement |

|  |  |

| Automatic splicer | Slitting & trimming knives automatic change system | Platform weighing scale system |

|  |  |

| Infrared align auto-adjustment | Color codesensor | Dedusting rollers |

|  |  |

| Pallet pusher | Auto-material flow | Inkjet coding system |