1.HSC-S series double knife sheeter adopts advanced design of synchronic rotary which

are driven directly by high power AC servo motor with high accuracy and clean cut.

2.And using our patent with embedded cutting head design, that its cutting cross profile

is straight and not pulling out fibers, this is key point to eliminate hairs of paper. Widely

used for cutting cardboard, coated paper, Kraft paper, culture paper, art paper, duplex,

packaging paper, etc. up to 1000gsm.

3.The machine is dedicated to produce sheet cutter , Products are well used and verified

by almost all top cosmetics and pharmaceutical packaging customers, and promise there

is no risk for long term running of your products in future. Consider this kind of machine

to improve quality and save cost, To improve efficiency .

|

|

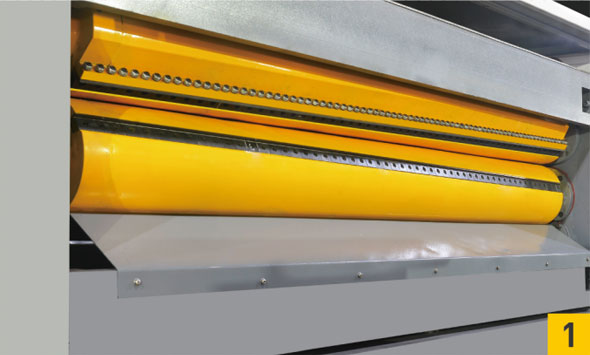

Double Rotary Sheeter Group Precision rotary sheeter groove is processed byimported advancedprocessing center with high accuracy and stability, cutting paper with-out burrs; High quality gear box, using no clearance design gear,meshing noise is low, life is twice longer than the traditional gear box;Good cast ductile iron wall and supporting parts, after aging treat-ment, again by imports of large vertical machining center, precisionhigh level requirements, processing error is smaller, the operation ofthe machine more stable and reliable.

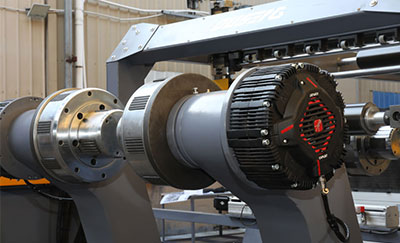

| Electric Control Part German imported Siemens PLC and The United States Emerson servodrive control system make the operation simpler and automatic.Cutting length, product number and the total number of fnishedproducts,etc. can be directly input and displayed on touch screentimely.The American CT servo drive rotary knife shaft, and cooperatewith energy storage cabinet, effectively reduce power consumption,improve effciency, reduce production cost |

|

|

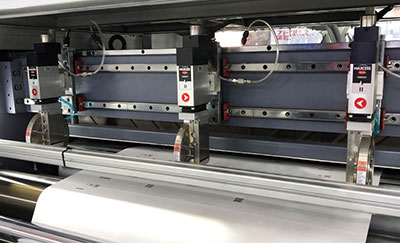

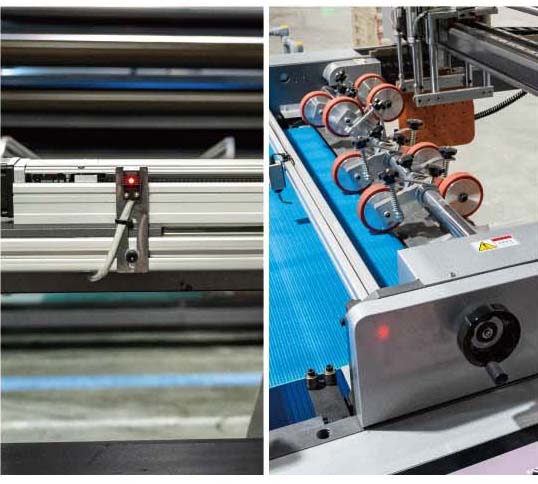

Slitting Knife Top shear air knife innovative desian enables pneumatic movement ofprecise adjustment for upper and lower knife, The pneumatic knife issuitable for wide range of application in light paper, plastic film, opticfilm and copper or aluminum foil different materials. Rigid knife holderhas excellent rigidity to perform high speed slitting up to 300m/minwith excellent slitting quality. | Conveying Overlap Part A precision structure can adjust the synchronous deceleration wheel,easy to operate, it's effective to protect surface of paper, so there willbe no scratching on surface, and also will not have the facula whenev-er speed is high or low. |

| Cutting Unit The double KNIFE cutting unit has a synchronic rotary cutting knifelike scissors on the material to make a smooth and accurate cuttingfor paper from 150gsm and up to 1000gsm.The knife roller is usingthe most powerful driver from UK CT. |

Double Arm Unwind stand with web tension controlsand pneumatic brake units. Adopt Italian RE control system and pneumatic componentsare adopted to guarantee the stable operation of thebrake control system and the accuracy of every aerodynamic action. |  |

| Three sets of MAXCESS pneumatic slitting knife |

Electric control partAdopt German imports of Siemens PLC and UK OF CT servo drive control system,make the operation more convenient, automation,cutting length, number and the total number of finished products, etc.,can be directly in touch screen input.High efficiency and energy saving ofhigh power CT servo drive rotary knife shaft,and cooperate with the energy storage tank,effectively reduce electricity consumption,improve the efficiency, reduce the production cost. |  |

| Transportation partsPatent device-A precision structure can adjust the synchronous deceleration wheel,easy to operate, it is effective to protect surface of paper,so there will be no scratching on surface,and also will not have the facula whenever speed is high or low . |

The delivery section using automatic set paper equipment (Jogger and vibrating devicesLift stacked set paper , the paper stack to a considerable height,which is automatically dropped.The stacker table has three sides shake finishing functions,and 1 unit Fixed plate which are vibrating and positioned laterally to |  |

| Reject Gate |

The new Anti curvature device (2 set de-curl )Effectively remove the curl of the roll to make the paper more flat,more conducive the paper roll tension stability. |  |

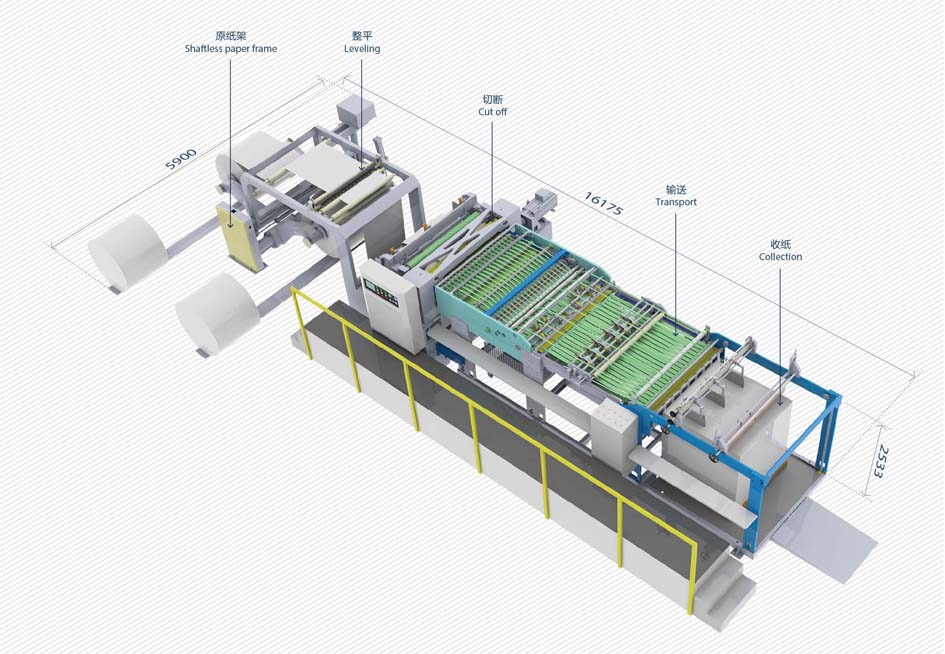

| ITEM | PARAMETERS | Cutting Length | Speed(m/min) | Speed (cuts/min) |

| Model | HSC 1500S/1700S/1900S | 1600≤X | 210 | <131 |

| Cutting Pattern | Double rotary sheeter | 1400≤X<1600 | 260 | ≥162<185 |

| Range of Gram Weight | 80-1000gsm | 1200≤X<1400 | 280 | ≥200<233 |

| Max.RollDiameter | 1800mm(71")Max | 1000≤X<1200 | 300 | ≥250<300 |

| Max.Paper Cutting Width | 1500mm/1700mm/1900mm | 800≤X<1000 | 300 | ≥300<375 |

| Total Power | 90kW | 700≤X<800 | 300 | ≥375<400 |

| Cutting Length | 400-1650mm | 650≤X<700 | 230 | ≥328<353 |

| Cutting Accuracy | +/-0.15mm | 600≤X<650 | 180 | ≥246<300 |

| Air Compressor Requirement | 0.8MPa | 550≤X<600 | 160 | ≥266<290 |

| Weight | 21000kgs/23000kgs | 500≤X<550 | 120 | ≥218<240 |

| Overall Dimension | L16175×W5900×H2533mm | 450≤X<500 | 90 | ≥180<200 |

| 400≤X<450 | 70 | ≥155<175 |

1. Automatic splicer

High performance automatic twin-head paper splicer with Taiwan control system

can splice paper automatically perform out by high flexibility and long service

life suitable for base paper which grams of 80-400gsm.

2. Slitting & trimming knives automatic change system

APS-L eries high precision automatic positioning and slitting system matches

high precision slitting requirements. Intelligently accurately and rapedly, the

slitting and trimming knives is auto-changing by manipulator, thus greatly

improving the ability and efficiency when product variety changing. According

to different cutting requirements it can work out different cutting solutions by

coordinating with different knife, such as automatic type manual type connected

type and pressure cutting type slitting knife and electronic knife, etc.

3. Platform weighing scale system

The weighing scale installed at the lifting platform can display the weight of the paper

stack timely for recording, It uses German technology and adopts four-horizontal and

four-vertical structure to avoid scale damage and measurement errors caused by the

displacement of paper stacks.

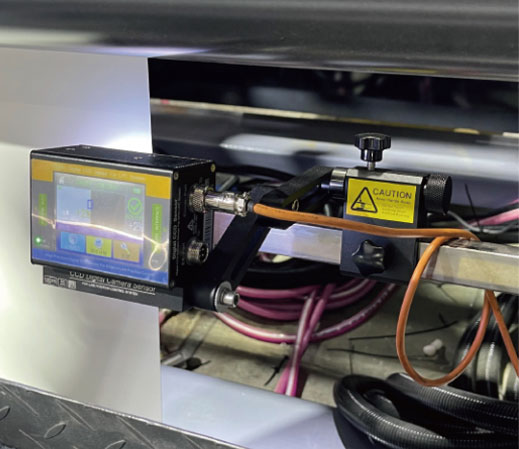

The height of the paper stack can be measured by laser rangefinder. The laser sensor emits

laser pulse, which are reflected back to the receiver by the stack, and it's height can be

calculated by the flight time of the laser pulse or the amplitude of the photoelectric signal.

4. Infrared align auto adjustment

The operator only needs to input the width in the touch screen, which can realize

the auto-alignment of the front and back paper rolls, avoid the loose and wrinkles

caused by the wrong alignment, reduce waste.This system co works with the order

auto changing system and all controlled by servo motor. It adops CCD correction

sensor and supports EPC and LPC line tracking.

5. Color code sensor

The high precision detector supplied by SICK a German brand can accurately identify

extremely fine color differences with the sensing distance tolerance up to +-5mm.

6. Dedusting rollres

The blue high viscosity roller can effectively adsorb the dust on the paper, and

then white dedust roller( driven by the cylinder) removes the dust. It's easy to

tear off the viscous film on the white one.

7. Pallet pusher

The lateral pallet auto-pusher is developed independently by HAOSHENG. The servo motor

drives the pushrod to push pallets from crossrange thus gear up for collection.

8. Auto-matreial flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor and uses the motor

drive the material transport in ultra-low postion straightly which is a modular design and

reach high degree of standardization. Hidden photo electric switch can prevent

photoelectric sensor or cardboard damage servo motor built-in to save space reversible

operation flexible adjustment basically maintenance-free.

9. Inkjet coding system

This part is composed of dedust system, high-speed inkjet system, intelligent positioning

system energy-saving LED curing system image detection system data management system

high-speed waste removal system type setting sofwware and printing software, Born for the

packaging industry.