HSC web cutting machine uses the advanced technique of Taiwan and Britain

The machine is driven by AC servo motor

The speed of cutting paper is fast and stable

Germany precise bearing and cutting knife assure the high cutting precision

Touch screen computer interface control simple operation, reasonable structure

Anti-noise stands to ensure smooth paper.

This machine is widely used in paper making paper products processing and printing industry and will improve efficiency and increase benefit for your company.

Single spiral upper knife enables better cutting result with low noise and less burrs

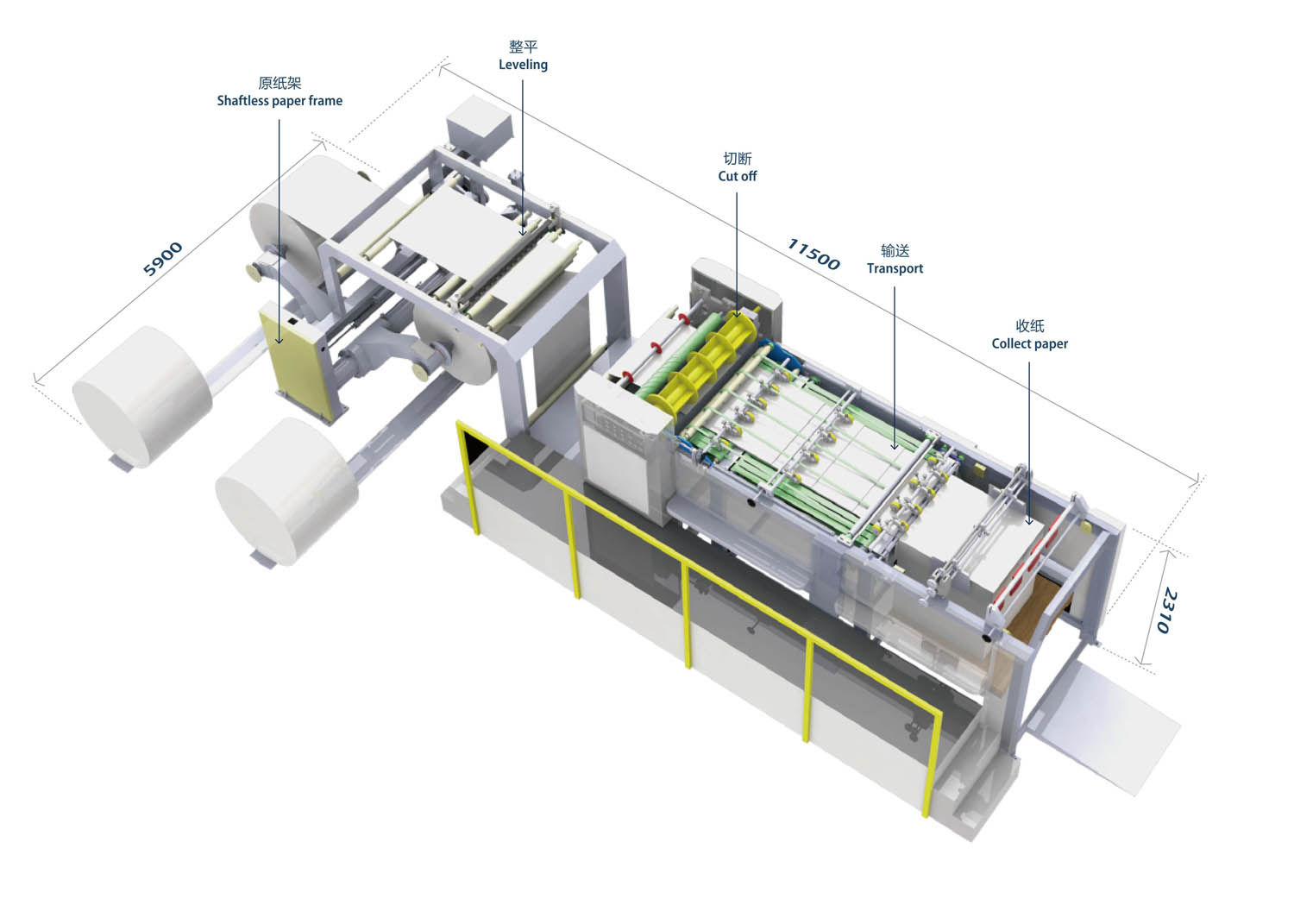

1.High-precision single knife cutting machine

2.Prismatic adjustment system for paper

3.Middle slitting and waste collection system

4.Automatic counting and label inserting equipment

5.Paper transporting equipment

6.Automatic paper trimming and collecting machine

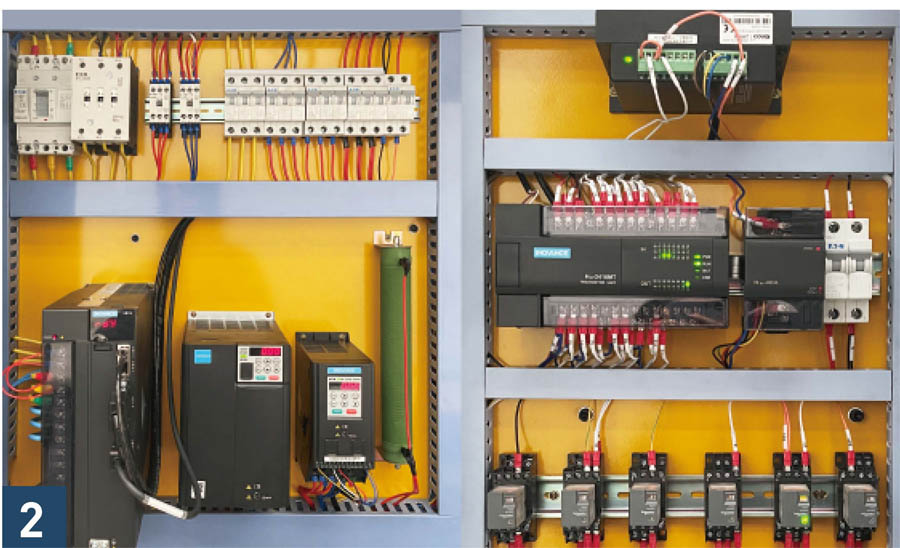

7.Electrical controlling system

8.Driving motor

9.Accessory

10.Double lime pneumatic shaft less paper rack

|  |

1. Cutting unit The upper knife uses British cutter method to | 2. Electronic control system The man-machine interface and TPC7062KS |

|  |

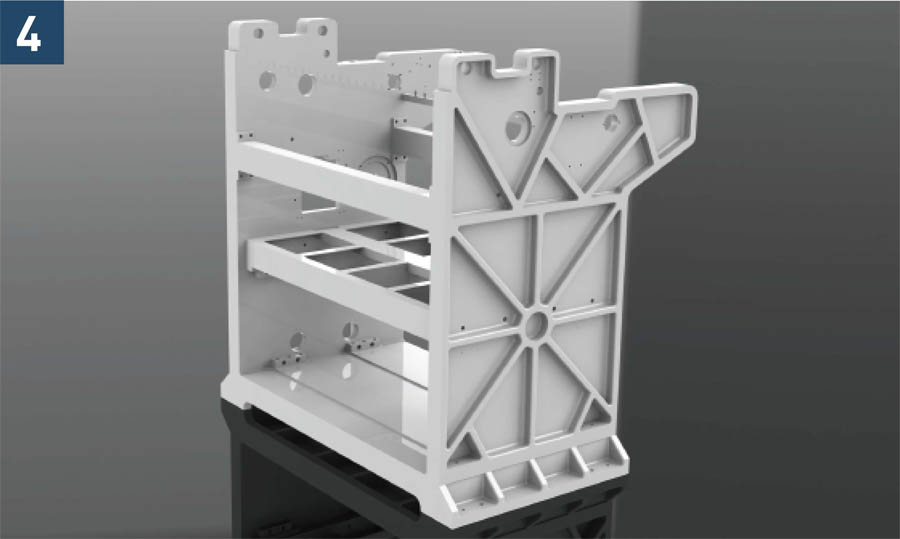

3. Curling device Curling device is in front of slitting device to | 4. The main machine structure The main machine wall is optimized through |

| Model | HSC 1400D/1700D |

| Reference weight of cutting paper | 50-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | ±0.3mm |

| Gross weight | 14000kgs/16000kgs |

| Total power | 28kw |

| Power consumption | AC380V/220V-50HZ |

| Maximum cutting speed | 400cuts/min |

| Cutting length range | 400m/min |

| Cutting length range | 400-1450mm/400-1650mm |

| Paper piling height | 1400mm |

| Maximum scroll diameter | 1800mm |

| Maximum paper cutting width | 1400mm/1700mm |

| The format of slitting | 2 sheet |

| The request for air compressor | Max 5.5kg/cm2×5m3/min |