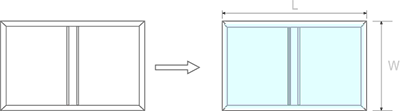

The paper is fed by feeder and glued. The semi-finished case is positioned on the paper, then pressed by two sets of rollers, finally finished the lining work. The end product is featured by its accuracy, neatness and nice appearance. It’s applicable to line the paper of hard covers, note book, calendar, package case, box file.

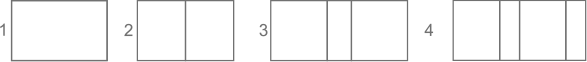

| 1. |

| 2. |

| 3. |

| . |

| 4. |

| Model | FD-AFM540S |

| Cover size(W×L) | Min: 100*200mm Max: 540*1000mm |

| Paper thickness | 100~200g |

| Cardboard thickness | 0.8~4mm |

| Precision | ±0.50mm |

| Speed up to | 25sheets/min |

| Electrical power | 10kw/380v 3phase e |

| Air supply | 10L/min 0.6Mpa |

| Dimension | 5600*1700*1860mm |

| Machine weight | 2200kg |

Remark:

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

3. We don’t provide air compressor.

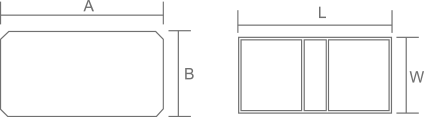

Technical parameter diagram:

|  |

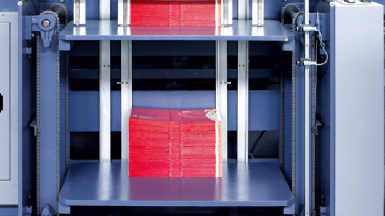

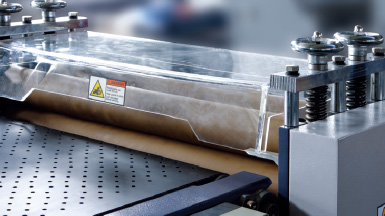

| Non-stop board feeder: The feeder can feed the paper without stopping, which ensure the production capacity | Two sets of rubber cylinders: Two sets of rubber cylinders are used to flatten the paper, which ensures the quality. |

|  |

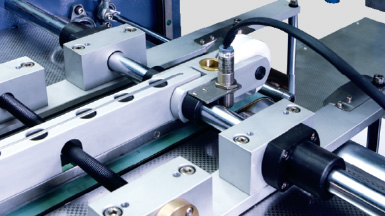

| Servo motor conveying board: The paper sucker device and servo motor conveying board ensures finished product rate | The ultrasonic double paper detector ensures: The ultrasonic double paper detector ensures the machine running and reduces the waste |