Classic model, mature technology, stable performance, easy operation, fast adjustment

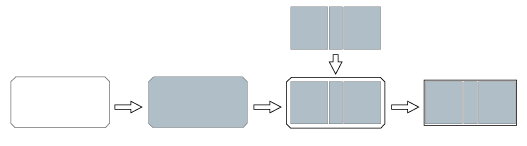

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process

there are features of accurate and quick positioning, and beautiful finished products etc.

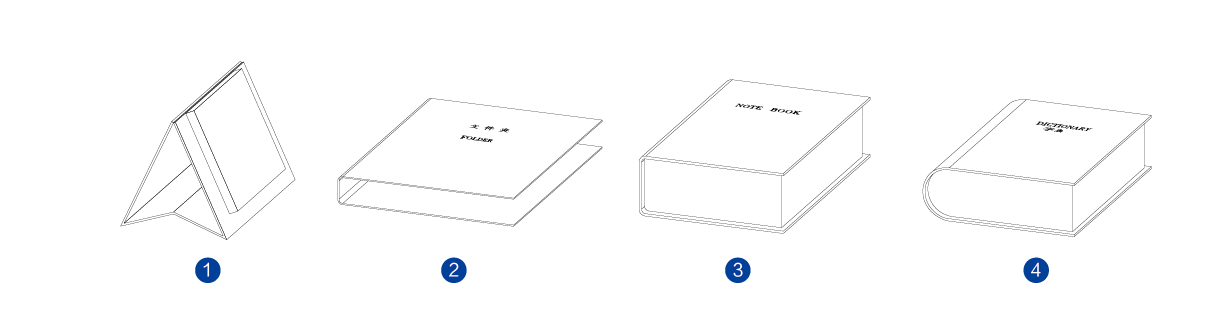

It is used to make hard covers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and irregular covers etc.

Model | FD-AFM540A | FD-AFM450A |

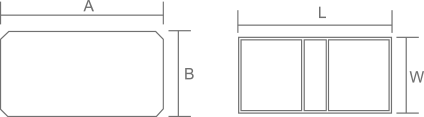

Cover size(W×L) | MIN: 100×200mm MAX: 540×1000mm | MIN: 100*200mm MAX: 450*800mm |

Paper size(A×B) | MIN: 130×230mm MAX: 570×1030mm | MIN: 130*230mm MAX: 480*830mm |

Paper thickness | 100-200g/m2 | 100~200g/m2 |

Cardboard thickness | 1-3mm | 1-3mm |

Spine size(S) | 10mm | 10mm |

Spine thickness | 1-3mm | 1-3mm |

Folded paper size | 10-18 mm | 10-18mm |

Cardboard number | 6pieces | 6pieces |

Precision | ±0.50mm | ±0.50mm |

Speed up to | 22pcs/min | 25pcs/min |

Motor power | 11KW 380v 3phase | 11kw/380v 3phase |

Air supply | 350L/min 0.6Mpa | 350L/min 0.6Mpa |

Dimension | L9000×W2400×H1550mm | L8000*W2200*H1550mm |

Machine weight | 3900kg | 3200kg |

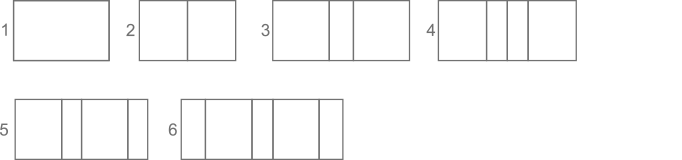

Cover type | 1/2/3/4/5/6 | 1/2/3/4/5/6 |

Remark:

1. The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

3. We don’t provide air compressor.

Case type:

|  |

| Adopt per-stacking non-stop bottom-drawn cardboard feeding device, which improves the production speed | The copper scraper cooperates with the glue roller by line-touch design which makes the scraper more durable. |

| |

| Pre-rectifying paper platform is equipped with ultrosonic double paper detector. |