1.The paper unloader can be used in conjunction with program-controlled paper cutters, lifters, paper breakers and air cushion workstations to form a cutting line, which can automatically complete the cutting, feeding and unloading, sorting, handling and stacking of paper, with many features such as high production efficiency, low operating labour intensity, short auxiliary production time and reduced labour costs.

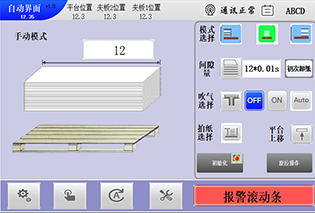

2.It greatly facilitates the feeding and unloading of paper stacks during the cutting process. The high quality stacking function provides the necessary prerequisites for future printing or folding processes, saving time and effort. The fully automatic paper size adjustment function guarantees simple operation.

|  |  |

| High quality steel beam | Computer touch screen | Servo drive |

|  |  |

| Patented overall frame type | Multi-servo control drive system | Inovance operation system |

Model | XZ1050K | XZ1650K | |

| Unloader type | Double plate | Double plate | |

Plate size | mm | 960*1340 | 1300*2040 |

Max paper format | mm | 900*1300 | 1270*1650 |

Min paper format | mm | 300*400 | 300*400 |

Max layer height | mm | 165 | 165 |

Max total height(with plate) | mm | 1600 | 1600 |

Max layer weight | kg | 350 | 450 |

Connected load | kw | 3.9 | 4.8 |

Air demand | bar | 6 | 6 |

Air consumption | l/min | 3 | 5 |

Packing size | cm | 318*208*224 | 396*240*235 |

Net weight | kg | 1500 | 2400 |